Piller

High-end service

from PILLER

We remove chips, burrs and dirt from your components

PILLER

Deburring and cleaning with high pressure.

The contract service from PILLER

We offer our customers contract services as capacity expansion - for small to large quantities without plant investment or as ramp-up support. We are the service provider for you with more than 20 years of know-how to bridge system delivery times or for short-term cleaning/deburring solutions. We deburr and clean for you quickly and reliably while meeting the cleanliness specifications.

When other deburring methods do not work, e.g. ECM, TEM, vibratory grinding or mechanical deburring, we deburr and fine clean in one and work exclusively with PILLER equipment. In addition, we develop and manufacture jigs and water tools (nozzles) in-house and can thus respond individually and flexibly to your requirements.

Our services at a glance

Deburring

Remove chips

Remove soiling

- High-pressure water jet (HDW) machining with up to 3,000 bar

- Removal of burrs, chips, mineralisation, sand residues, welding beads, hardening residues, overspray

- Parts from the industries: Automotive, hydraulics, electronics, pneumatics, aviation, mechanical engineering in general

- Machining of parts with a wide range of geometries and materials

- Light metals, steel, any cast variants, brass, thermosets

- Workpiece dimensions from 5 mm³ to components of size approx. 1,000 x 800 x 600mm

- Unit numbers from 1 to several million per year

- Component weight from 1g to 200kg

- HDW Processing, rinsing, drying, packing

- Preservation of components only with RoHS-compliant additives

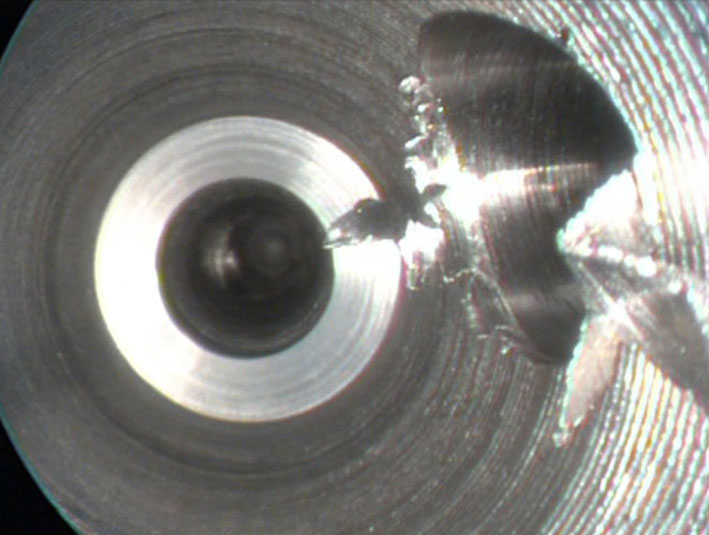

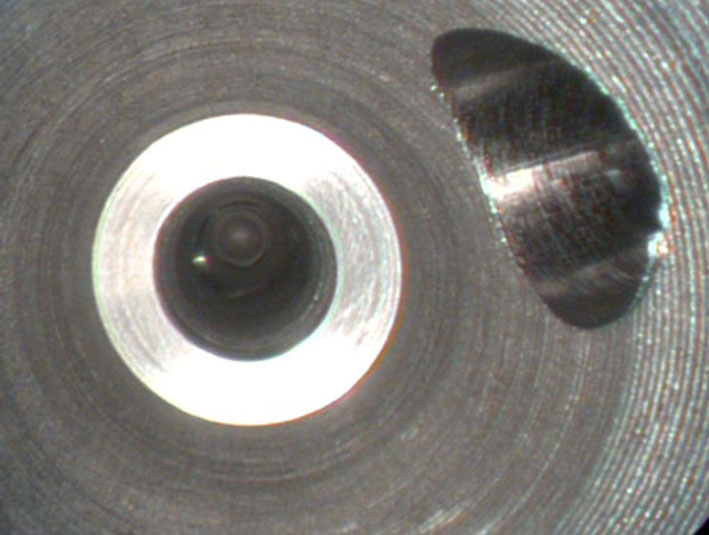

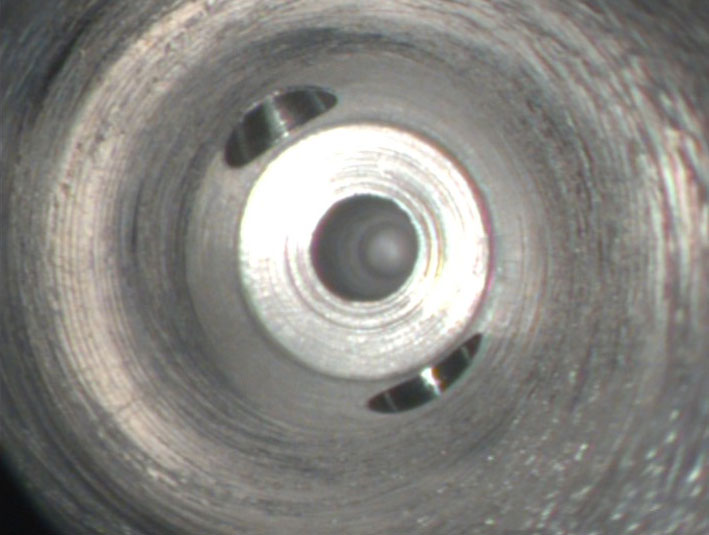

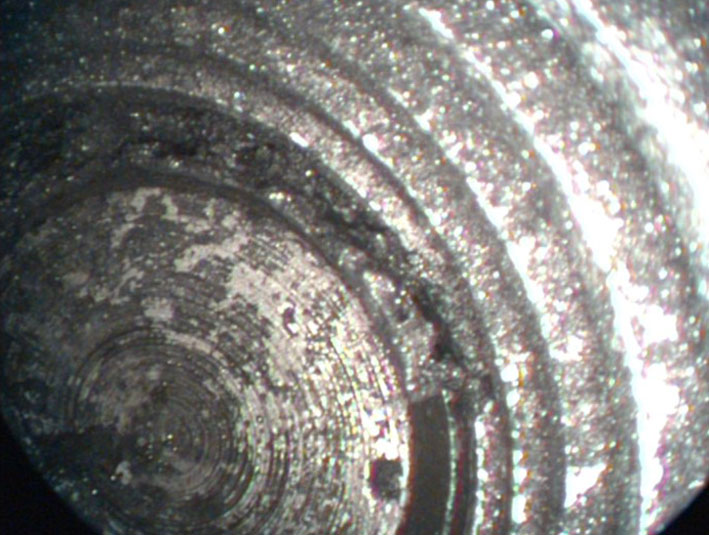

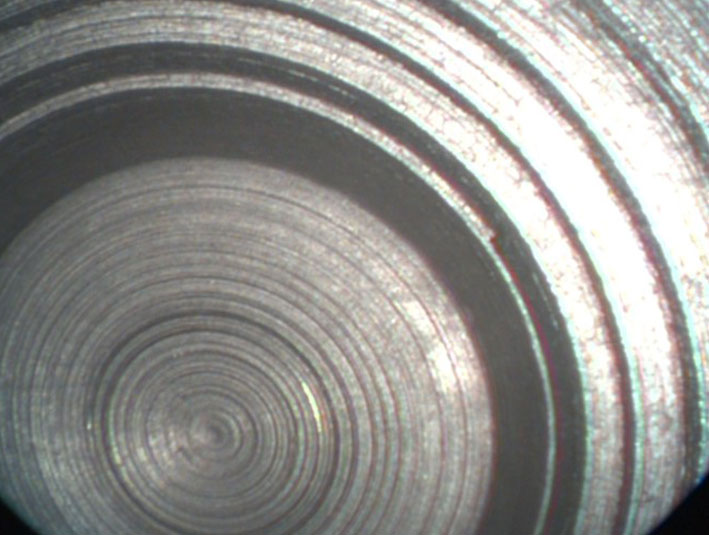

- Documentation of the processing with endoscope or microscope

- Residual dirt analysis according to VDA19

Advantages

- More than 20 years of experience in deburring workpieces with high pressure

- Machining on PILLER systems of the type VectorJet II, VectorJet III, MultiJet

- In-house production of jigs and nozzles (water tools)

- Residual dirt analysis in the house (inline)

- Short lead times

- Carrying out trials and feasibility studies

- No damage to the components during HDW machining

Quality assurance

- Clearly structured processes and experienced staff

- Highest quality standards

- DIN ISO 9001:2015 certified

- Requirements of the automotive, hydraulics, aerospace, pneumatics and medical technology industries are met

- Residual dirt analysis according to VDA19

- Examinations and protocols

Piller

Equipment for contract manufacturing

Benefit from more than 20 years of experience in deburring workpieces with high pressure. We work exclusively with equipment developed in-house and can therefore respond to your individual needs. We develop and manufacture jigs and water tools ourselves. This allows us to react flexibly and reliably to your requirements.

VectorJet II

(5 lines) for HDW machining of smallest parts up to the size of 600 x 400 x 200mm

VectorJet III

(2 lines) for all part sizes, but mainly for larger parts (up to 800 x 800 x 600mm or up to max. 1200 mm part length); part changeover takes place parallel to HDW processing

MultiJet

(2 lines) for large quantities of one type of component in dimensions up to Ø 40mm.

Vacuum dryer

(4 plants) for all component sizes

Elke Rentschler

Contact person for contract services

Do you need payroll services?

Your professional for deburring

metal

With innovative processes and state-of-the-art technology, we ensure precise and reliable deburring solutions that are individually tailored to your requirements. We offer you a wide range of processes to optimize the deburring process for your workpieces. Electrolytic deburring enables extremely precise processing and is particularly suitable for complex geometries. Thermal deburring of plastic also reliably removes burrs from sensitive components. With ultrasonic deburring, we process delicate workpieces such as gear wheels or small parts gently and precisely.

Laser deburring ensures a highly accurate and burr-free surface, while dry ice deburring is an innovative and chemical-free solution. We achieve clean results regardless of the material. When deburring plastic parts, we ensure smooth surfaces and the highest quality. We also attach great importance to attention to detail when deburring aluminum. For industrial applications such as copper pipe deburring or stainless steel pipe deburring, we offer processes that are as efficient as they are reliable. Even for steel deburring, we rely on robust and proven solutions that meet even the highest requirements.

Our machine solutions are perfectly tailored to different requirements. The drum deburring machine is particularly suitable for deburring small parts and delivers outstanding results. With a continuous deburring machine, we can process large quantities in continuous processes. For flexible applications, we rely on the electric deburrer, which is versatile and can be used for a wide variety of tasks. We are proud to offer you a wide range of deburring options. Whether it's the precise deburring of gears or the processing of special materials - we find the perfect solution for every challenge. Contact us today and benefit from our experience and expertise.