PILLER

The specialists

for industrial parts cleaning

State-of-the-art machines, comprehensive service, component processing in the shortest possible time - PURE PERFECTION.

PILLER

For over 25 years:

Cleaning and deburring with high pressure

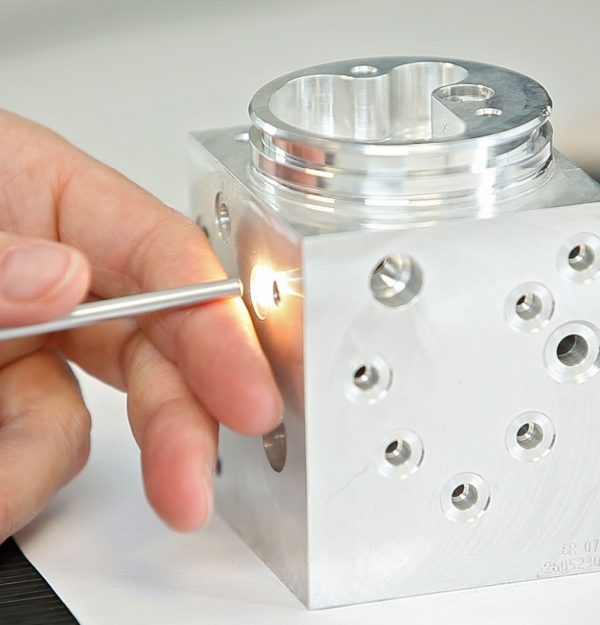

Since 1995, we have been providing flexible and innovative solutions in deburring technology at our Ditzingen site near Stuttgart. Through our consistent orientation towards the challenges of future markets, we have positioned ourselves as a leading company in the field of industrial high-pressure blasting technology with water, cutting oil or cooling lubricant. Patented processes make it possible, with a pressure of up to 1100 bar (high pressure), to direct the water or cutting oil jet specifically onto the workpieces to be processed in order to remove burrs, chips and other contamination. The permanent development of our technologies is particularly close to our hearts. Our proven systems are now available in modular design. Here, functionalities such as pre-cleaning, fine cleaning and VE rinsing as well as pre-drying of the components by spinning and blowing off have been integrated into the process.

Particularly in the case of electromobility components, the topics of burr-free and technical cleanliness play an even more important role than before. With our modular approach, Piller has found an answer to the questions of car manufacturers and suppliers who are looking for high-performance and compact systems to meet the increased requirements economically in the future.

Rolf Nick, Managing Director of PILLER Entgrattechnik GmbH

Our history:

The specialists for industrial parts cleaning

1995

Foundation of the PILLER company by Thomas Piller / Market launch of the PILLER double chamber

1998

Market launch of the PILLER VectorJet II

2000

Market launch of the PILLER MultiJet

2002

Expansion: Foundation of PILLER Kft (Hungary)

2003

Market launch of the PILLER special solutions for crankshafts

2004

Market launch of the PILLER RoboJet and PILLER VectorJet III

2005

Expansion: New production hall and new administration building

2006

Market launch of the PILLER RoboJet Twin

2007

Market launch of the PILLER VectorJet IV

2009

Market launch of the PILLER VectorJet IV as a camshaft solution

2010

Entry of J/N Beteiligungs GmbH / Market launch of PILLER car washes

2011

New partner: PILLER Cleantech SARL (France) founded / Full-range supplier for high-pressure deburring and washing technology

2011/2012

Expansion: New production hall for service deburring

2012

Market launch: Inline residual dirt analysis

2014

Entry of SüdBeteiligungen GmbH and VR Equitypartner GmbH / New development of car wash systems

2015

Presentation of HPU 650 for integration of high-pressure jets / Market launch of the PILLER VectorJet IV with rotary transfer principle / Expansion: Planning of new assembly hall

2016

Market launch of the PILLER VectorJet IV for rotationally symmetrical parts

2017

Market launch of the PILLER VectorJet IV and washing for crankshafts

2018

Entry of Riflebird Capital

2020

Takeover: PILLER bought by SFO Group from Munich

2021

Redesign of the PILLER website

PILLER

For over 25 years:

PURE PERFECTION.

PILLER deburring, cleaning and drying systems are known for their high processing quality, durability and reusability. State-of-the-art machine solutions, which can be optimally adapted to the respective customer requirements thanks to our modular construction principle, makes us one of the leading specialist suppliers in the field of industrial cleaning. We supply our customers worldwide and across all industries. Our success is based on our employees, some of whom have been with us for over 25 years. We are proud of this. But we also invest in the future. Since 2021, we have been a recognised training company of the Chamber of Industry and Commerce and are pleased to have started with three trainees in different professions.