Contact

No chance

for burrs and chips

State-of-the-art machine solutions from PILLER: everything from a single source.

Products

Whether standard machines or customised designs,

we have the right solution - efficient and process-safe.

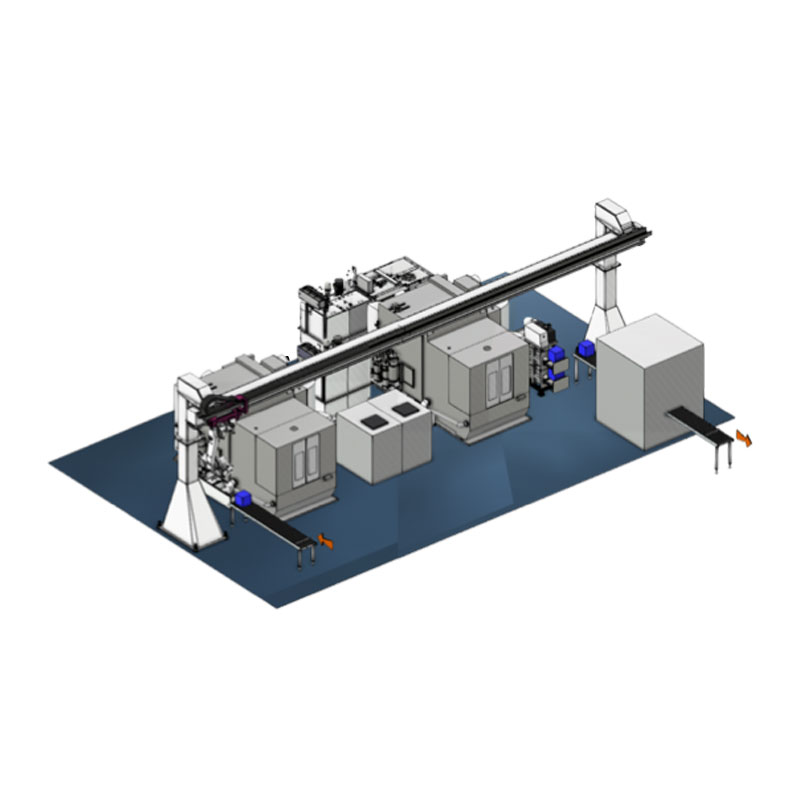

We can not only represent the sub-processes such as deburring or cleaning, but also efficiently map the complete process including the control and handling of the components: from pre-cleaning to deburring, fine cleaning, drying or cooling. We develop jigs and water tools ourselves - this enables us to implement individual processing strategies and achieve the best results in reproducible quality. For example, the strict residual dirt specifications of VDA19 for the automotive industry and suppliers are no problem with our innovative cleaning systems, even with short cycle times.

Through constant further development of our system concepts, we are now able to offer you solutions for the entire deburring and fine cleaning process integrated in one system. This integration is also possible in our new VECTOR JETIII double spindle machine, which is designed for the shortest cycle times thanks to the double spindle concept.

Piller

Deburring systems

Piller

System/complete solutions

If you need space-saving, energy-optimised systems, we are your competent partner. In your project, our experienced project managers integrate and adapt standard modules, or we develop individual systems and special solutions for you. For flow production concepts or the design of machining islands, we are also happy to work together with other machine suppliers.

Precise and efficient deburring machines

For high-quality metal deburring solutions. With innovative technologies and high-performance deburring machines, we ensure that your components achieve the highest quality and precision. Our range includes a wide spectrum of processes and tools that have been specially developed for different materials and applications. Our triangular deburrers are the ideal solution for processing hard-to-reach areas and reliably removing even the smallest burrs. We attach great importance to precision, especially when removing stainless steel burrs, to ensure flawless surfaces.

Gear deburring, for example on gears, requires maximum precision, which we ensure using state-of-the-art processes. Our high-performance deburring machines are designed for a wide range of applications and guarantee clean results. For water jet deburring, we rely on an environmentally friendly and innovative process that has been specially developed for sensitive materials. We have specially designed deburring machines for processing sheet metal. The sheet metal deburring machine and our sheet metal deburrer deliver precise results when reworking sheet metal edges and ensure a flawless surface. Metal deburring includes a variety of processes that we adapt to the requirements of your components. One of the most efficient processes is explosion deburring, which is ideal for hard-to-reach burrs. For processing stainless steel, we also offer chemical deburring, a technique that uses chemical processes to achieve perfect surfaces. Even plastic deburring is part of our range of services, allowing us to guarantee excellent results even with plastics.

Automated processes such as robot deburring enable us to guarantee high precision and efficiency for large quantities. The deburring of components is one of our core competencies, regardless of whether they are small or large components. Turned parts deburring requires the utmost care to ensure flawless functionality, as does bore deburring, which involves the precise removal of burrs in bores. We offer specialized solutions for tubes, such as our tube deburring machine, which is designed to meet the requirements of a wide range of sizes. Sheet metal deburring rounds off our portfolio and enables customized post-processing for optimal further processing. Our technologies guarantee the highest quality, optimized processes and a long service life for your products. Let us optimize your production processes together and find the best solution for your requirements. Contact us today to find out more about our innovative deburring solutions.