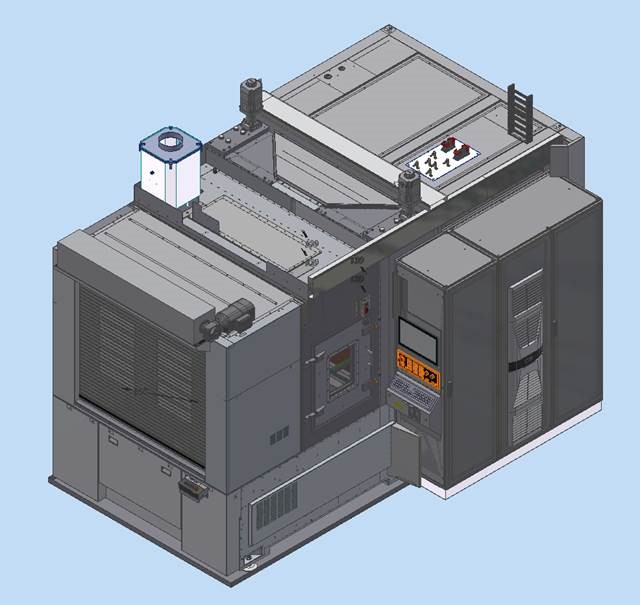

VectorJet III twin spindle

Highly flexible CNC high-pressure waterjet deburring machine with fast swivel table and bulkhead. On the swivel table there are two rotary tables (B-axes) on each side of the table, which are separated by a centre wall. This creates a division into front and rear working chambers. The front working chamber (loading chamber) can be expanded into a fully-fledged cleaning chamber by means of a special front attachment. Machining is carried out with up to two horizontal machining axes per component with different nozzle equipment. The VectorJet III DS is suitable for large series and can be loaded using automation (gantry, robot).

Advantages

- Main time parallel loading

- Six-sided machining for workpieces up to 250 kg

- Multiple voltage

- Large machining area

- Large heavy parts

- Easy to automate with gantry, robot or other handling systems